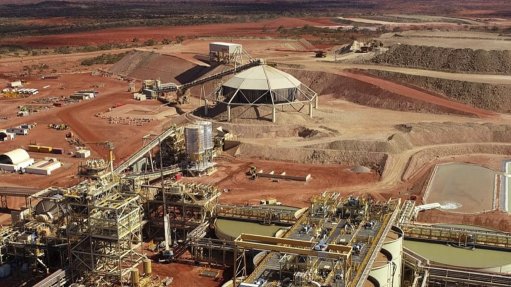

SA mining supply chain firms struggling but current efforts raise hopes of better fortunes

STRUGGLING SECTOR The local mining supply chain industry is struggling, as the market is currently “dominated” by international players

Photo by Creamer Media's Dylan Slater

OSSIE CARSTENS The ease of procurement globally has put local manufacturers on “very shaky ground”

PAUL JOURDAN Advancing the South African mining cluster through implementation of the Mining Charter could maximise the local mining supply chain industry

Photo by Creamer Media's Dylan Slater

BRANDON IRSIGLER An empowered mining supply chain is the next step in transforming the mining sector and is necessary

With the advent of democracy in South Africa, the ease of procurement globally put local manufacturers on “very shaky ground”, as they had to compete internationally almost overnight, while their market share contracted, Mining Equipment Manufacturers of South Africa (Memsa) CEO Ossie Carstens says.

This, combined with a lack of growth in the local mining sector over the past 15 years, resulted in the stagnation of the local mining supply chain and manufacturing sectors in South Africa, he states.

With gross domestic product (GDP) growth for 2019 expected to reach only 1.5%, Carstens says local mining supply chain stakeholders are struggling, as the market is currently “dominated” by international players.

An increased focus by mines on buying locally, where possible, and increased efforts to educate local manufacturers on government incentives for business would assist the local mining supply chain sector to grow and develop, he adds.

Gearing up to reverse the development is not the problem, but South African miners have shown a predilection for imported goods, laments independent consultant Dr Paul Jourdan. The quality and standards of local products are often regarded as inferior. However, he says, clarity on the available range of locally manufactured products will be facilitated through the implementation of a standardised coding and product identification system.

Original-equipment manufacturers (OEMs) will have a full view of the local content of their products when such a system is properly implemented.

Carstens believes that the system, if properly managed, could be the catalyst to drive localisation and beneficiation.

It is envisioned that every supplier to an OEM will have to produce a verified certificate of the product that it supplies, which includes the country of origin, as well as the origin of the raw materials and details about the labour and logistics involved.

Upstream, the same processes will have to be repeated, ultimately leading to a full view of the weighted effect of the verified material and labour used in the manufacture of the product.

The same product verification can then be used for other OEM products.

“It means that the product, rather than the company, will be verified, dramatically reducing the cost of verification,” Carstens explains to Mining Weekly.

Once the procurement is done, an OEM can assemble its product or equipment using its verified products, labour and logistics costs, and can then produce a certificate of local content and origin.

“If this is well implemented and controlled, it will provide local OEMs with a competitive advantage over their international competitors, as it will ease the mine’s efforts to produce a similar certificate for the Department of Mineral Resources and Energy (DMRE).”

Looming Threat No More

Despite the perceived threat of mechanisation and automation looming over South Africa, Jourdan believes that these should be considered job-neutral opportunities, as several studies have indicated that the jobs lost to mechanisation in mining are roughly equal to those gained in the local supply chain, provided that the machines and systems are not imported.

Following the South African Mining Supply Chain Conference in May, Jourdan says: “Advancing the South African mining cluster through implementing the Mining Charter could maximise the local mining supply chain industry, create local mining equipment manufacturing capabilities and modernise South African mining.”

He tells Mining Weekly that this modernisation would ameliorate the crisis in South Africa’s gold and platinum sectors and, with machines operating through digital systems and doing the dangerous work, there is potential to create a “massive” mining supply chain industry.

Ideally, future mining should be taking place “using a joystick”, with employees on the surface, away from danger, Jourdan says. If the machinery was locally manufactured, this would ensure higher-quality and safer jobs, similar to jobs in the automotive sector.

This was the rationale underlying Mining Phakisa, he says, stating that South Africa needs “customised solutions for its mining problems”.

Further, with global miners often ceasing operations, owing to the depths to which they need to mine for resources, Jourdan suggests there is an opportunity for South Africa’s mining supply chain industry to be the world leader in deep-level mining technologies, including ventilation, machinery, communications and software.

Law firm Dentons partner Brandon Irsigler agrees, adding that foreign investors and distributors should be educated on the benefits of partnering with an empowered local entity, and that both parties must actively engage in establishing mutually beneficial processes.

He also highlights the importance of being mindful of World Trade Organisation treaty obligations, which generally means that “the State has a legal obligation to treat imported and local goods equitably”.

Mining Charter Implementation

Through the implementation of the Mining Charter, mining and mining supply chain companies could turn their supply chains into a source of sustainable competitive advantage, says Carstens.

An empowered mining supply chain is the next step in transforming the mining sector and is necessary, Irsigler adds.

While procurement is weighted at 40% of the Charter’s scorecard, Irsigler points out that the subtargets are weighted and measured pro rata to achievement, which, when added to other elements of the Charter, form an overall snapshot of the manufacturer’s alignment with Charter values – of which black equity ownership in a mining right is “still the most essential”.

Carstens, meanwhile, believes that the Charter presents a window of opportunity that could allow for significant growth in mining supply chain and associated industries.

With the Charter stipulating local procurement, and, given that the Charter is legally binding, the “natural effect of it will be growth in the manufacturing sector”, he says.

This will manifest not only in the areas where the mines are located but also nationally – upstream – in the mine’s supply chain.

The Charter sets specific target parameters in terms of the time allowed to meet the target and the total procurement percentage to be achieved, Carstens explains. Thus, the window of opportunity is the time local manufacturers require to prepare their capacity and ability to replace imports.

The Charter further requires that the procurement of all goods bought by the mine be done using a standardised coding system and that local content be verified by the South African Bureau of Standards or a similar body.

However, Charter implementation has not been without its challenges, says Carstens.

Memsa has reached out to the DMRE and Minerals Council South Africa to assist in clarifying some of the ‘tricky’ details in the Mining Charter.

This includes whether the meaning of local pertains to only the town where the mine is located or South Africa in general. “Either one can have some serious repercussions, in that local procurement might never reach the target if there are logistical difficulties, or it might just be the injection that a specific economy needs,” Carstens states.

Memsa has, in the interim, “defaulted” the definition to ‘national’, he explains.

Development Strategy

Recent political changes across Africa have created new hope for the mining industry and have led to renewed impetus to support the African Mining Vision (AMV). The AMV is cited as a pathway, formulated by African nations themselves, that puts the continent’s long-term and broad development objectives at the heart of all policymaking concerned with mineral extraction.

South Africa is uniquely positioned to support this vision, especially considering that the Mining Phakisa process has laid a solid foundation for the country to play a key role in achieving that vision, says Jourdan.

However, the recognition of regional local content to achieve greater mining supply chain economies of scale has to go hand in hand with a system that discounts “richer” countries in favour of the “poorer” countries, he tells Mining Weekly.

Recommended in the draft Southern African Development Community Regional Mining Vision is “the recognition of country neighbours at the inverse of GDP per capita”, Jourdan notes. This would mean that the highest GDP per capita in Africa would count towards only 50% of local content for another country, and the lowest GDP per capita would count about 90%.

“The developmental focus of this approach has garnered it broad support, and the overall benefits to South Africa in terms of market access and regionwide industrial growth could be significant,” Jourdan says.

Moreover, with renewed focus on the National Development Plan, the Mining Phakisa outcomes have resulted in renewed support for research and development (R&D) in the mining industry, as well as support for localisation in the manufacture of mining equipment for domestic use and export.

In terms of R&D, the Mandela Mining Precinct is cofunded by Minerals Council South Africa and its establishment bears testimony to innovative efforts by government, industry and other stakeholders to collaborate towards strengthening the South African mining industry and mining supply chain.

In identifying the need for R&D, a focus on the mining extraction phase is required. Jourdan notes that, within this context, a combination of fundamental and applied research is required to satisfy industry requirements in the short, medium and long term.

Consequently, R&D needs to be integrated into system design and development, with the necessary fundamental research to allow for and support such design.

This also includes the involvement of OEMs, through Memsa, to facilitate the development of the identified technologies to commercialisation.

Jourdan suggests that initiatives such as the Mining Phakisa would “need to be institutionalised and become a regular forum, with the objective of zero harm, mining viability and building the supply chain”.

The impact would include employment, government revenue and strengthening the balance of payments for mining and the mining supply chain, as well as training and higher education.

However, “much better interaction” with labour would be needed to make it a success, Jourdan advises.

The Minerals Council has provided financial support for various programmes under the South African Minerals Extraction Research and Development and Innovation initiative and pledged a 1:2 funding ratio with the Department of Science and Innovation.

The initial commitment from the department amounted to R213-million and a yearly funding amount averaging R100-million has materialised to date.

This initiative has seen Minerals Council executives being involved in collaborative efforts that will contribute to sustainable, viable and socially acceptable mining.

Further, the Department of Trade, Industry and Competition’s pilot Cluster Development Programme supported Memsa for the first two years, during which its membership grew to 33 companies, ranging from exempt microenterprises to established OEMs.

New resources now need to be identified to continue building the South African mining supply chain cluster.

For its part, the Mandela Mining Precinct is playing a direct role in mining supply chain development, with recent projects including the development of a product and technology database, which is expected to be launched later this year.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation