Optimise comminution processes with FLSmidth’s Eccentric Roll Crusher

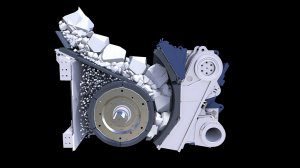

ERC® crusher cutaway showing the screening and crushing chamber process

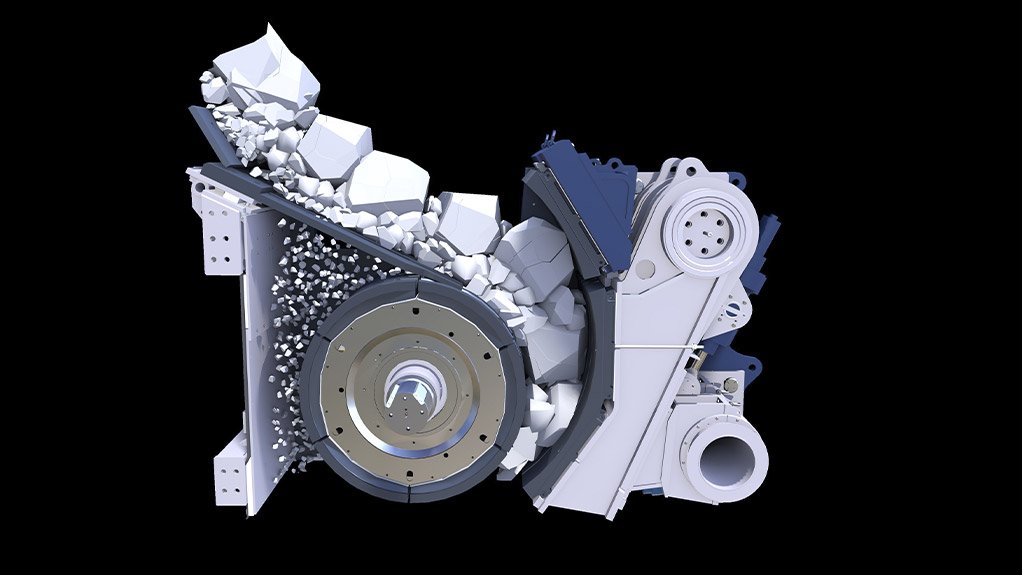

Cutaway of low profile ERC® primary crusher showing the apron feeder

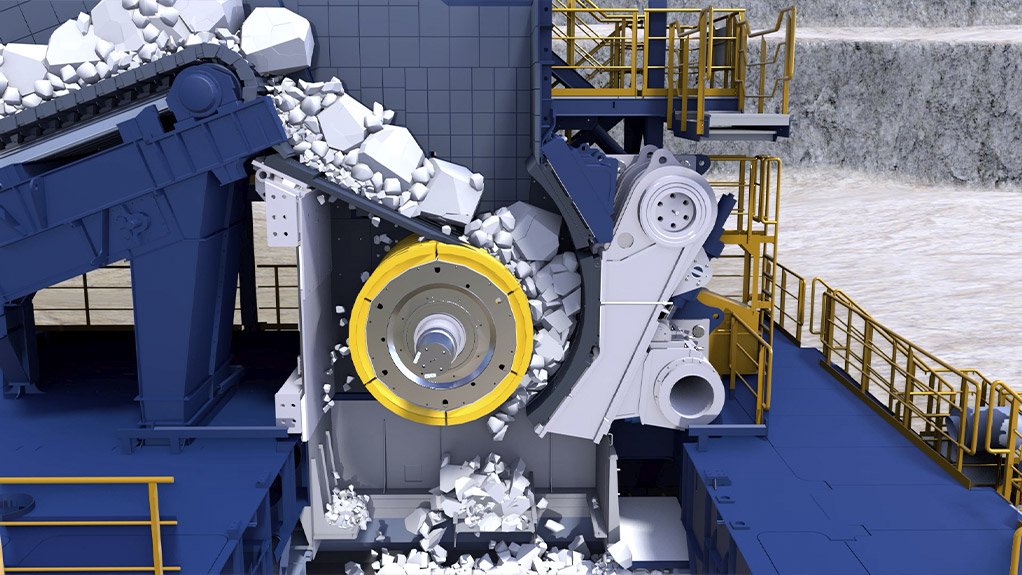

Low profile ERC® primary crushing plant installation

An installation with a ERC® 22-20 primary crusher

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

The energy-intensive nature of comminution processes has led to FLSmidth’s efforts to develop more energy efficient equipment. One such technology is the patented Eccentric Roll Crusher (ERC®) which, through its innovative design, not only reduces energy consumption in the primary crushing of hard rock, but also offers increased throughput and reduced wear.

Comminution by its nature is an energy intensive process, and its efficiency not only impacts the overall energy consumption of processing plants but also improves the sustainability of mining and quarrying activities. Ideally suited for use in both underground and surface operations, the ERC® offers significantly higher efficiency and flexibility than any conventional crushers in the processing of hard rock, says Demitri Kokoroyanis, Regional Product Line Manager – Crushing & Screening, Sub-Saharan Africa, Middle East & South Asia Region (SSAMESA) at FLSmidth.

“A particularly effective kinematic of the oscillating roll with constant stroke in the entire crusher cavity allows for a higher reduction ratio and more effective use of crushing energy,” he says. “The reduction ratio of 1:10 potentially allows for elimination of secondary crushing stages, depending on the material characteristics.”

In addition, the high moment of inertia of the roll and flywheels contributes to accumulated crushing energy, reducing the power requirements and effectively compensating load peaks in the comminution process.

Key design features of the ERC® are compactness and robustness. Due to its low profile, the crusher offers a construction height up to 50% lower than other hard rock primary crushers. This compact design and the reduced number of components simplifies transportation, installation and maintenance, and also lessens CAPEX costs by up to 10%.

The integrated pre-screen allows for efficient bypassing of fines, boosting crusher capacity as well as reducing energy consumption by up to 40% and increasing liner life in the process. Bypassing fines also reduces the risk of compacting and overloading of the crushing chamber.

“Mine operators and quarry owners can also benefit from the higher service life of wear elements on the roll,” says Kokoroyanis. “The back-turning of the roll occurring during the crushing process distributes the loads over the entire circumference. This prevents local wear zones and results in uniform wear.”

With impact resistance and wear in mind, the large chunks of feed material in the crushing chamber do not fall directly onto the mounted working element, but hit the hood, which is significantly more resistant to such loads than other components. That is a key advantage over many conventional primary crushers.

“As more and more mine operators become aware of the benefits of this innovative technology, we are seeing a great deal of interest in the ERC® range. We have already sold several units over the past four years, with some being installed in Laos, Asia, and, we hope, soon in Angola,” concludes Kokoroyanis.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation